Thu, Dec 12, 2024

[Archive]

Volume 16, Issue 1 (March 2019)

IJMSE 2019, 16(1): 22-28 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Darrudi H, Adelifard M. Influence of Deposition Temperature as a Reducing Agent on Synthesis of Reduced Graphene Oxide (RGO) Nanosheets. IJMSE 2019; 16 (1) :22-28

URL: http://ijmse.iust.ac.ir/article-1-1106-en.html

URL: http://ijmse.iust.ac.ir/article-1-1106-en.html

Abstract: (19990 Views)

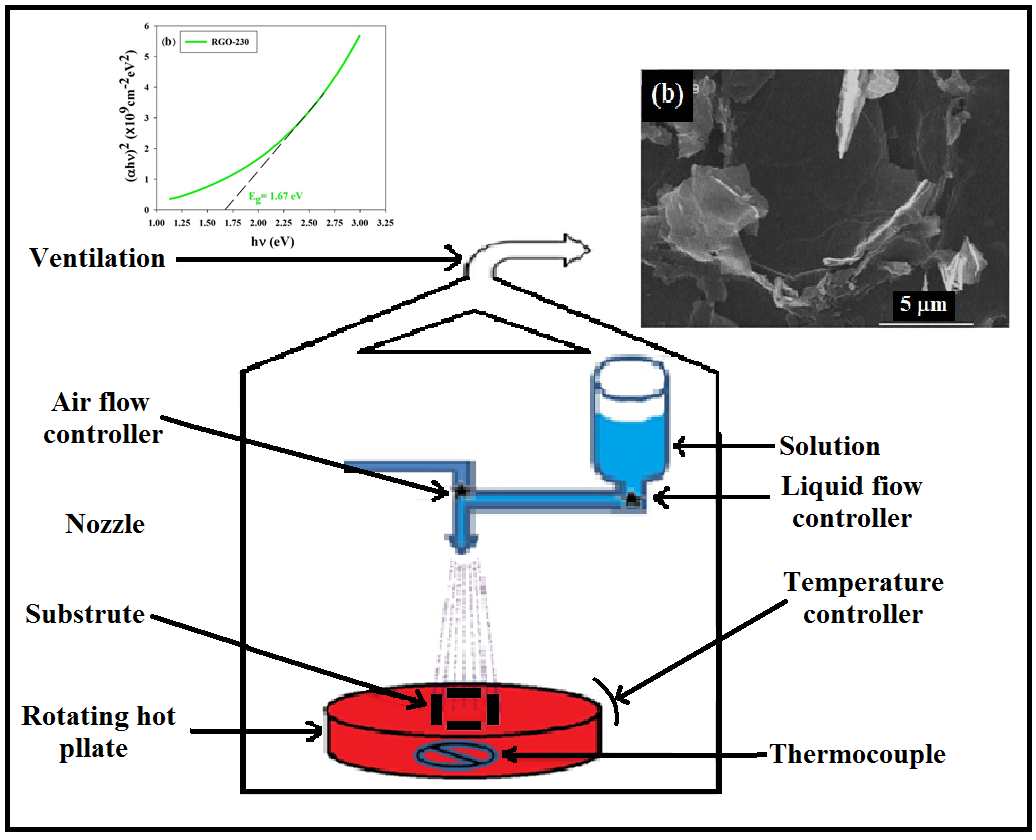

In this paper we have investigated the physical properties of reduced graphene oxide (RGO) thin films prepared at various substrate temperatures of 230, 260, 290, 320 and 350 oC using spray pyrolysis technique. We have compared these films from various viewpoints, including structural, morphological, optical, electrical and thermos-electrical properties. XRD analysis showed a phase shift from graphene oxide (GO) to RGO due to elevate the substrate temperature from 200 oC to higher temperatures. FESEM images of RGO thin films reveal that a stacked image of irregular and folding nanosheets, and rod-like features at temperatures below and above 290 oC; respectively. Optical studies showed that the layers have a relatively high absorption coefficient (∼0.8×104 to 1.7×104 cm−1) in the visible range, with an optical band gap of 1.67–1.88 eV. The Hall effect data showed that all samples have a p-type conductivity with a hole concentration of ∼1015 cm−3, and sheet resistance values of about 106 Ω/sq, in agreement with previous reports. The thermoelectric measurements revealed that with increasing applied temperature gradient between the two ends of the samples, the thermoelectric electromotive force (emf) of the prepared RGO thin films increases.

Type of Study: Research Paper |

Subject:

Ceramics

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |