Fri, Dec 13, 2024

[Archive]

Volume 17, Issue 2 (June 2020)

IJMSE 2020, 17(2): 92-103 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Ghasemian Safaei M, Rastegari S, Latifi R. The Effect of Powder Composition on Cyclic Oxidation Behavior of CO-Deposited Al-Si Cating on Nickle-Based Superalloy. IJMSE 2020; 17 (2) :92-103

URL: http://ijmse.iust.ac.ir/article-1-1201-en.html

URL: http://ijmse.iust.ac.ir/article-1-1201-en.html

Abstract: (13057 Views)

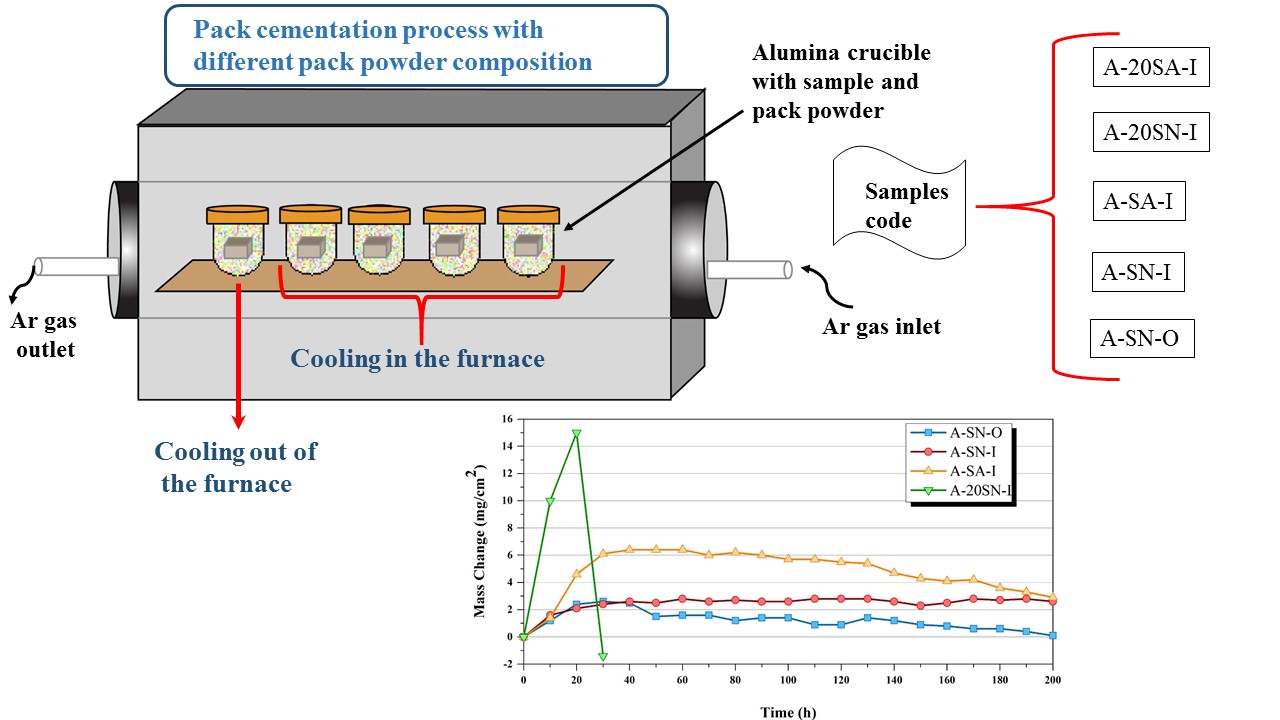

In this study, Si-modified aluminide coating on nickel-base superalloy IN-738LC was prepared using a pack cementation method with various powder compositions at 1050 °C for 6 h. The cyclic oxidation test was conducted at 1000 °C followed by cooling at room temperature for 200 h and 20 cycles. The effect of powder composition and the way of cooling on the coatings microstructure and oxidation behavior were studied. Investigations carried out using a scanning electron microscope (SEM), EDS analysis, and XRD. Microstructural observations revealed that the coating thickness of 293 and 274 µm was achieved in the case of using pure Al and Si powder and alloyed Al-20wt.%Si one in the packed mixture, respectively. It was also found that utilizing pure Al and Si powder with NH4Cl as an activator in the pack led to the formation of silicide coating, owing to the higher diffusion of Si, which showed superior cyclic oxidation performance.

Type of Study: Research Paper |

Subject:

Ceramics

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |