Mon, Mar 3, 2025

[Archive]

Volume 20, Issue 3 (September 2023)

IJMSE 2023, 20(3): 1-11 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Porhonar M, Shajari Y, Razavi S H, Seyedraoufi Z. Mechanical and Microstructural Evaluation of Recycled AA7075 Swarf. IJMSE 2023; 20 (3) :1-11

URL: http://ijmse.iust.ac.ir/article-1-2578-en.html

URL: http://ijmse.iust.ac.ir/article-1-2578-en.html

Abstract: (8639 Views)

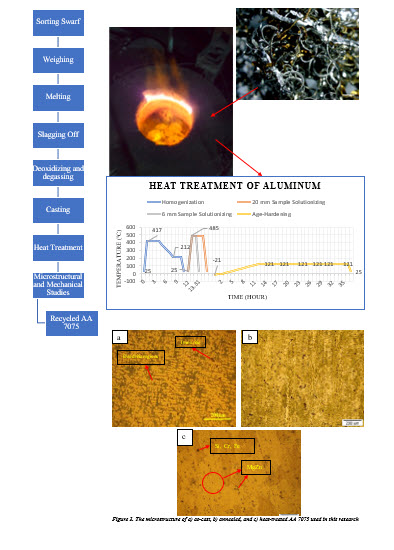

In this research, after pressing in a cylindrical mold, the AA 7075 alloy swarf was melted and cast in a wet sand mold. After rolling and cutting, sheets with two different thicknesses of 6 and 20 mm were obtained. The sheets after homogenization were solutionized at 485°C for 30 and 90 minutes, respectively, due to differences in thickness and thermal gradients. The solutionized samples were quenched in 3 polymer solutions containing 10, 30, and 50% Poly Alekylene Glycol. The results showed that melting, casting, rolling, and heat treatment of AA7075 alloy swarf similar properties to this alloy is achievable. Microstructural studies by optical microscopes (OM), Field Emission Scanning Electron Microscopy (FESEM), and X-ray diffraction (XRD) showed that by increasing the quenching rate after the solutionizing process, precipitation increases during aging. The tensile test results indicated that as the quench rate and internal energy increase, the diffusion driving force would increase the precipitation of alloying elements. Hence, this leads to an increase in hardness and reduction of its strain after aging.

Type of Study: Research Paper |

Subject:

Polymers

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |