Fri, Dec 13, 2024

[Archive]

Volume 20, Issue 4 (December 2023)

IJMSE 2023, 20(4): 1-8 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Ghaemifar S, Mirzadeh H. Unveiling the Affect of Annealing Temperature on the Phase Transformations of Inconel 718 Superalloy Manufactured by Additive Manufacturing. IJMSE 2023; 20 (4) :1-8

URL: http://ijmse.iust.ac.ir/article-1-3304-en.html

URL: http://ijmse.iust.ac.ir/article-1-3304-en.html

Abstract: (7390 Views)

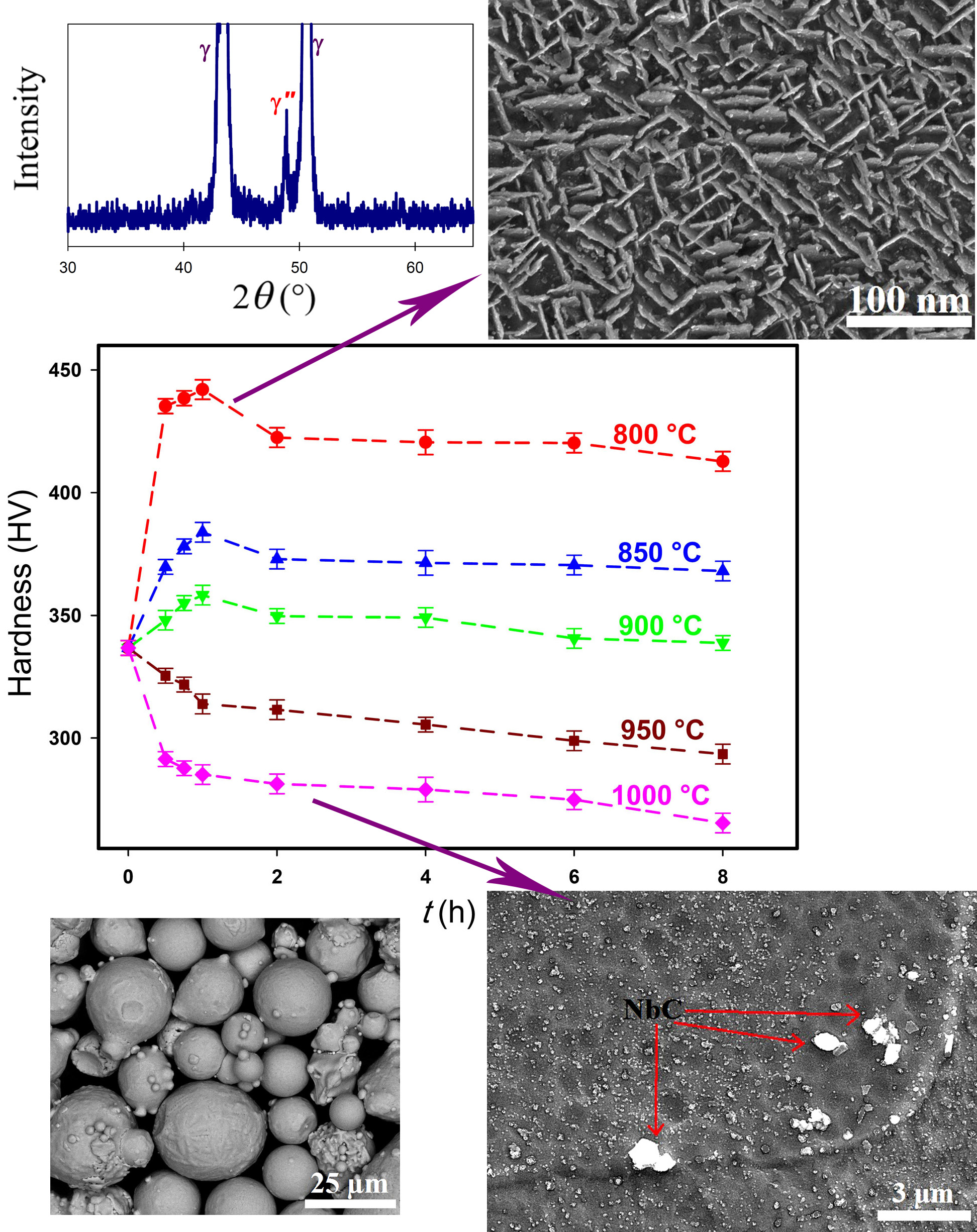

Phase transformations and the evolution of hardness during elevated-temperature annealing of Inconel 718 superalloy manufactured by the laser powder bed fusion (L-PBF) were investigated. The microstructural evolution, elemental analysis, phase formation, and hardening were characterized by scanning electron microscopy, energy-dispersive spectroscopy, X-ray diffraction, and Vickers indentation test, respectively. It was observed that the effect of annealing treatments is directly governed by the annealing parameters (i.e. time and temperature), for which the hardness measurement as a fruitful and convenient tool can reveal this effect. The increase of the hardness, which was obtained by the annealing (aging) treatments at the temperature range of 800-900 °C, indicated precipitation of the Ni3Nb γ˝ strengthening phase; while owing to the coarsening of precipitates as a results of overaging at this temperature range, the hardness decreased. For instance the length and aspect ratio of precipitates in the aged sample at 800 °C for 1 h is 67.14 nm and 0.32, respectively; while these values in the aged sample at 800 °C for 8 h is 78.34 nm and 0.44, respectively. On the other hand, the decrease of the hardness at temperatures of 950 and 1000 °C was attributed to the decrease of dislocation density in conjunction with the Ni2Nb Laves phase dissolution. Hence, it is crucial to determine the annealing parameters according to the required microstructure and properties.

Keywords: Nickel-based superalloys, Additive manufacturing, Aging heat treatment, Homogenization treatment, Precipitation strengthening

Type of Study: Research Paper |

Subject:

Influence of processing and post-processing on microstructure and mechanical properties

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |