Tue, Mar 4, 2025

[Archive]

Volume 16, Issue 4 (December 2019)

IJMSE 2019, 16(4): 63-72 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Latifi R, Rastegari S, Razavi S H. Effect of ZR Content on Oxide-Scale Spallation of Aluminide Coating. IJMSE 2019; 16 (4) :63-72

URL: http://ijmse.iust.ac.ir/article-1-1278-en.html

URL: http://ijmse.iust.ac.ir/article-1-1278-en.html

Abstract: (20047 Views)

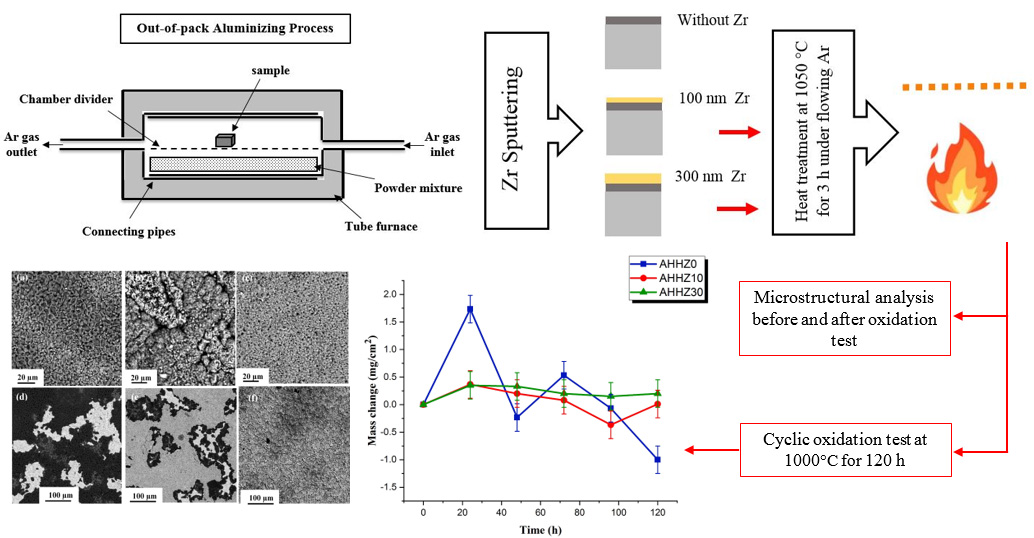

In the present study, Zirconium modified aluminide coating on the nickel-base superalloy IN-738LC was first created by high activity high temperature aluminizing based on the out-of-pack cementation method. Then, Zr coatings were applied to simple aluminide coatings by sputtering and heat treatment in order to study the effect of Zr on the coating microstructure and oxide spallation. Microstructural studies were conducted by using scanning electron microscopy (SEM), Energy Dispersive X-ray Spectrometry (EDS), and x-ray diffraction (XRD) microanalysis. The results indicated that zirconium modified aluminide coating, like aluminide coating, has a two-layer structure including a uniform outer layer of NiAl and an interdiffusion layer in which zirconium is in a form of solid solution in the coating. Furthermore, the 300nm Zr-coated NiAl demonstrated an excellent scale adhesion, a slow oxidation rate and lower amounts of some other elements such as Ti and Cr in its oxide layer leading to a pure aluminide oxide layer.

Keywords: diffusion aluminide coating, zirconium modified coating, oxidation resistance, out-of-pack cementation

Type of Study: Research Paper |

Subject:

Ceramics

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |