Thu, Dec 12, 2024

[Archive]

Volume 21, Issue 4 (December 2024)

IJMSE 2024, 21(4): 11-29 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

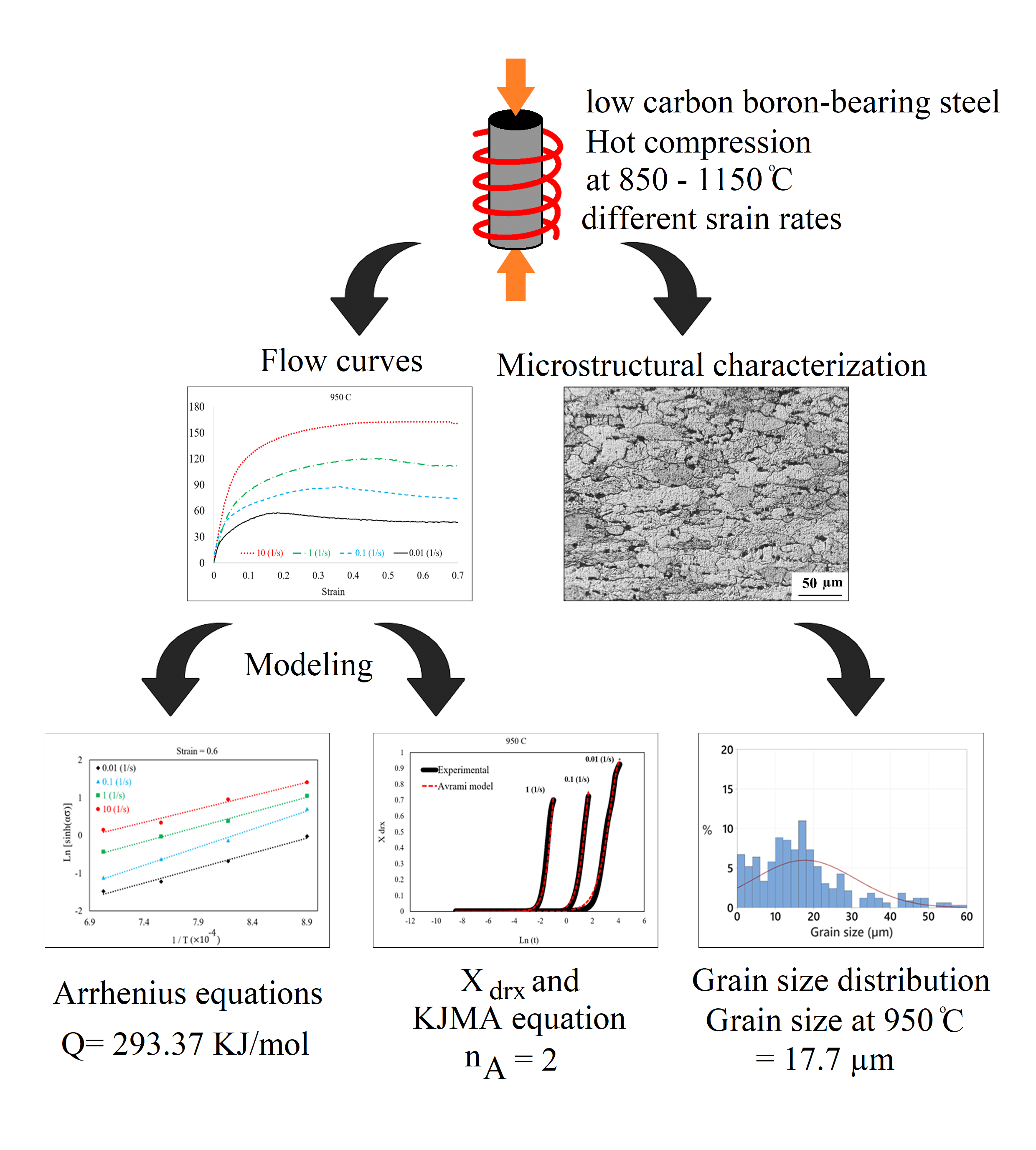

Mirghasemi S M, Mohammad Sahrifi E, Borhani G H, Seyed Beigi M. Modeling of Hot Deformation and Dynamic Recrystallization Behavior of Boron-Bearing Low Carbon Steel Using Hot Compression Flow Curves.. IJMSE 2024; 21 (4) :11-29

URL: http://ijmse.iust.ac.ir/article-1-3512-en.html

URL: http://ijmse.iust.ac.ir/article-1-3512-en.html

Abstract: (2174 Views)

In this study, the hot deformation and dynamic recrystallization behavior of low carbon steel containing 21 ppm boron was investigated. After homogenizing the samples at 1250 ℃ for 1-hour, hot compression tests were conducted at temperatures ranging from 850 ℃ to 1150 ℃ and strain rates from 0.01 to 10 s⁻¹, resulting in strain-stress flow curves. Following corrections, calculations and modeling were performed based on Arrhenius equations. Among them, the hyperbolic sine relationship provided the most accurate estimate and was selected as the valid model for the applied strain range. According to this model, the deformation activation energy (Q), was determined to be 293.37 KJ/mol. Additionally, critical and peak stress and strain values were obtained for each temperature and strain rate, and power relationships were established to describe their variation with respect to the Zener-Hollomon parameter (Z). Recrystallization fractions were derived by comparing the hypothetical recovery curves with the material flow curves, and the results were successfully modeled using the Kolmogorov-Johnson-Mehl-Avrami (KJMA) equation. The Avrami exponent was measured at approximately 2, indicating that nucleation predominantly occurred at grain boundaries. Microstructural analysis revealed that at higher Z values, recrystallization occurred along with a fraction of elongated grains, while lower Z values resulted in a greater fraction of equiaxed dynamic recrystallization (DRX) grains. The average grain sizes after compression tests at 950 ℃, 1050 ℃, and 1150 ℃ were measured as 21.9 µm, 30.4 µm, and 33.6 µm respectively at a strain rate of 0.1 s⁻¹, and 17.7 µm, 28.7 µm, and 31.3 µm at 1 s⁻¹. The overall microstructure displayed a more uniform grain size distribution with increasing deformation temperature.

Type of Study: Research Paper |

Subject:

Synthesis and preparation of materials to meet the requirements of AM techniques

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |